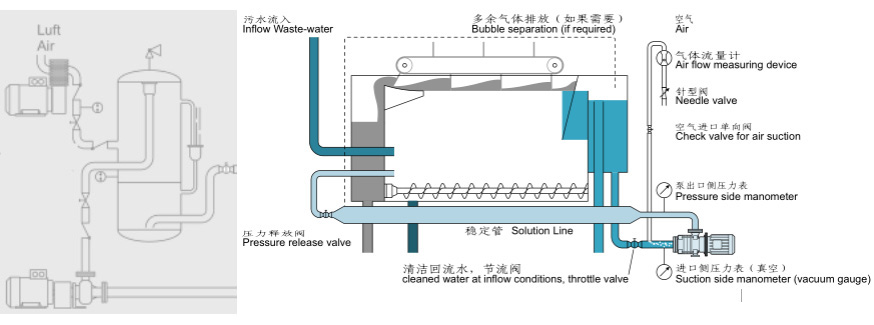

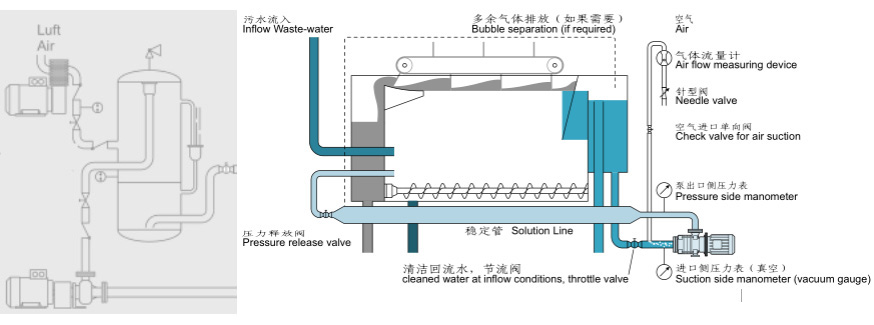

Working Principle:

Dissolved Air Flotation

Dissolved air flotation (DAF) is a reliable and proven process for purification in wastewater systems. DAF is used for the easy separation of suspended matters in liquids. The DAF System works by saturating the process water with air under high pressure which is then released to normal pressure and piped into the wastewater tank. The micro bubbles generated during pressure release work to attract suspended particles in the liquid and float them to the surface where they are then skimmed away.

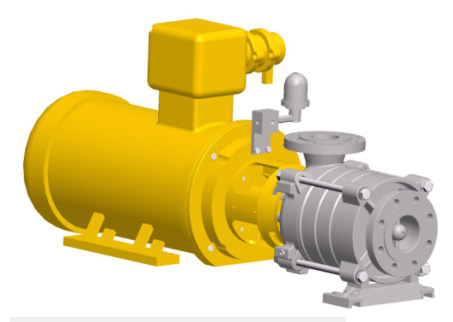

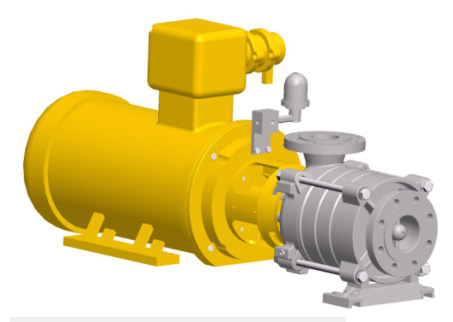

Specification (DN80):

1.Max Flow rate: 50m3/h

2.Rotate Speed: 2900rpm/min

3.Max Head: 100M

4.Inlet & outlet: DN80 & DN60

5.Material: Super-Duplex for Volute, Impeller and Shaft

6.Working Pressure: 145PSI

Advantage compared with conventional system

*Open impeller structure ensures the stability and reliability of the gas-liquid mixing conveying, and its energy-saving effect is remarkable

*Depending on the pump model selected, gas contents up to 30% can be achieved successfully for stable transport condition.

*By gas-charging of liquid grades of solubility up to 100% are realized

*The dispersion contains micro bubbles as fine as possible with an average size smaller than¡Ü 30 microns and an equal distribution.

*Gas fed directly from the inlet of the pump allows the reduction of DAF system components ( air compressor, pressure vessel, releaser, control system and valve, centrifugal pumps) compared to traditional DAF system and new system is greatly simplified and realiable.

AF application include the treatment of oilwater emulsions, fat separations, phosphate precipitations and heavy metal precipitations as well as final sedimentation at bio-treatment plants. Multistage flotation plants are a solution for the treatment of special waste.

Mineral Processing

Mineral Processing

Most copper mining depends on crude ore that is cracked,grinded in rock crushers and subsequently supplied towards the flotation. Fine air bubbles transport the small mineral particles to the water surface and keep them in the flotate. By means of the water-air mixture and adding of flotation additives at the same time the copper ore is separated from other ores. The ore concentrate subsequently is smelt in the following process.

Induced Gas Flotation Petro Industry

The induced gas flotation also is a well-proven process in the petro industry for the separation of oil-water mixtures. For the crude oil extration in special flotation system feeding of e.g.natural gas is applied. World wide multi-phrase pumps substitute extensive conventional plants because of its advantage shows above.

Fuel Production

In the processing of regenerative energy carriers such as biofuel, wood, waste fractions with high heat value, or animal meal to synthesic gas the inert CO2 has to be washed out. The mico-bubble generator can perfectly wash out the CO2.

Treatment of Cooling Lubricants

Treatment of nonpolluting cleaned cooling lubricants for example out of the milling prcess for steel.

*Cleansing Agents Treatment

*Ammonia Stripping Plant

*Elimination of Lime

*Outgasing during LPG Pumping

*Cooling Water Treatment by Ozone

1.Max Flow rate: 50m3/h

1.Max Flow rate: 50m3/h

Mineral Processing

Mineral Processing