Multiphase Liquid Dissolved Oxygen Pump

Ⅰ、Product picture

II、Basic theory

The maximum solubility of gas in water mainly depends on the pressure, water temperature and mixing, the higher the pressure, the lower the water temperature, the greater the saturation solubility of air in water. The more mixed cutting times, the more dissolved gas volume.

In the air flotation device, the Veritas Multiphase Liquid Dissolved Oxygen Pump is used. The gas is directly inhaled in the pump inlet pipe using its own vacuum. The special impeller structure of Veritas Multiphase Liquid Dissolved Oxygen Pump (multi-stage cutting and pressurization) enables the pump to fully dissolve the gas and liquid two phases and reach high pressure saturation during the pressure building process. During the decompression release, the dissolved gas escapes in the form of microbubbles and disperses in the air flotation device. Bubbles created in this way can be less than 30 microns in diameter.

According to the properties of gases and liquids, and their temperature and pressure changes, the gas in the liquid

Saturation solubility varies. Pump performance is very stable when flow changes and gas volume fluctuations.

The traditional air flotation device dissolves the gas through the static pressure of the dissolving tank, and must be equipped with a series of related equipment, such as air compressor, dissolving tank, water pump, control system, release device, valve, etc. Since the gas cannot be saturated in water, it is easy to produce large bubbles after decompression release, which affects the effect of air flotation treatment. Using gas-liquid multiphase pump to dissolve gas can not only save most of the equipment, reduce the investment and operating costs, but also greatly improve the effect of air flotation treatment because of the fine and uniform dispersion of bubbles.

Compared with jet pump dissolved gas system pipe dissolved gas, Veritas multi-phase flow pump dissolved gas is completed in the pump multi-stage pressure boost process, gas solubility is easy to control, dissolution effect is more ideal.

The efficiency of air flotation treatment using Veritas multiphase flow pump is much better than that of jet pump dissolving gas system.

1. Micro bubble manufacturing:

• High-speed rotation, breaking bubbles, forming stable micro bubbles;

• The pressure increases, generating saturated dissolved gas water;

• Micro bubbles + saturated dissolved gas water.

2. Air float: The bubble consists of the pressure reduction to release the dissolved gas and the micro-bubbles formed by cutting.

3. Reaction type: improve mass transfer efficiency (area), carried out under high pressure (blade pressurization + cutting to generate micro-bubbles).

4. Degassing: Increase the inlet air flow, suitable release port design (nozzle, forming local low pressure, increasing gas-liquid contact area).

III、Performance Parameters Of The Pump

In order to capture the most suspended solids, the bubbles in the air flotation should be as small as possible and evenly distributed. The Veritas multiphase pump can generate bubbles smaller than 30 microns, achieving the most ideal effect.

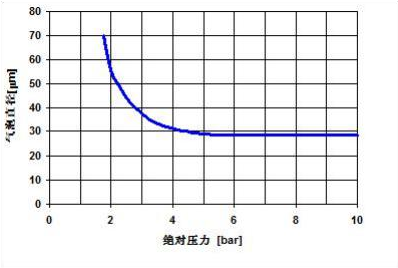

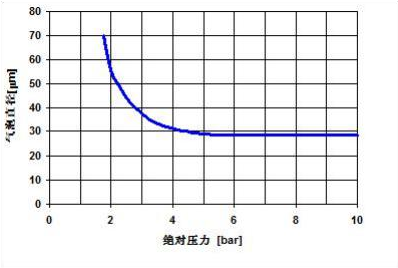

The following figure shows the relationship between bubble size and saturation pressure after pressure reduction (medium: air and water, temperature 20 º C).

The selection principle of Veritas pump is as follows:

2.1 The flow rate of dissolved water can be determined according to the process requirements, and can generally be considered as 25% -35% of the water volume for air flotation treatment.

2.2 Refer to the above figure for pressure. Diagram showing the relationship between bubble size and saturation pressure after reducing pressure in the medium. To ensure that the diameter of the released bubbles is ≤ 30 μ m. Generally, the selected pressure is ≥ 4.0 bar (gauge pressure), depending on the process design.

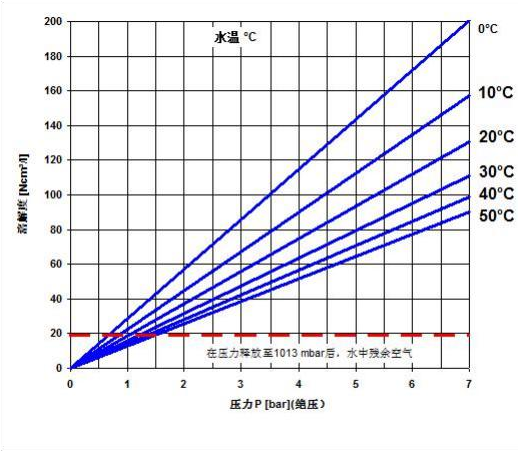

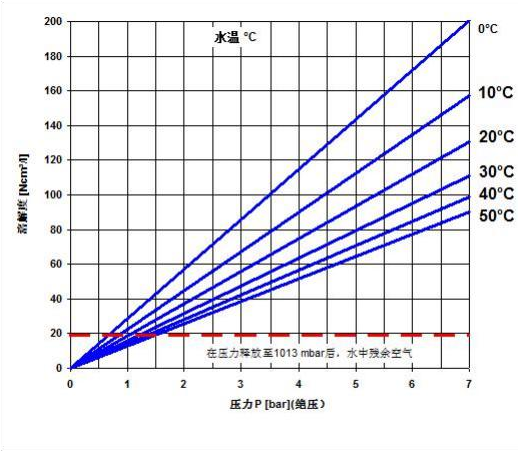

2.3 The saturation solubility of gas-liquid ratio gas (oxygen, air) in water depends on the temperature and pressure of the water. The saturation solubility of gas (oxygen, air) in water under different temperature and pressure conditions can be obtained from the physical property parameter chart of the medium. The above figure shows the saturation solubility of air in water. After obtaining the saturation solubility of the effluent, the gas-liquid ratio of the pump should be the same or similar to the saturation solubility of water. Under normal circumstances (dissolved water pressure of 4 bar, water temperature of 20 º C), the gas-liquid ratio is taken as 9%.

IV、 Product Features

1. Cavitation: Open impeller, suitable material selection to prevent cavitation.

2. Dirty medium: Suitable, not suitable for blockage, and not prone to scaling.

3. Release process: forming controllable bubble concentration and particle size.

V、 Product application

1. Various types of air flotation.

2. Mining (copper ore, flotation solids).

3. Ammonia removal (water treatment, addition of air, removal of ammonia).

4. Ammonium chloride regeneration (environmentally friendly etching of circuit boards).

5. Dissolve ozone (water treatment, excluding CODS).

6. Increase the reaction rate of reactions that prioritize gas-liquid mass transfer.

VI、Product performance parameters

|

Model

|

VRT-1.5

|

VRT-2.2

|

VRT-3

|

VRT-5.5

|

VRT-11

|

VRT-18.5

|

|

Motor Power (kW)

|

1.5

|

2.2

|

3

|

5.5

|

11

|

18.5

|

|

Gas Content

|

10%

|

10%

|

10%

|

15%

|

20%

|

20%-30%

|

|

Recommended dissolved gas water flow rate through pump (m ³/ H)

|

0.5-2

|

2-3

|

3-4

|

8-12

|

20-30

|

45-60

|

|

Inlet/Outlet pipe diameter (mm)

|

DN32

|

DN32/DN40

|

DN32/DN40

|

DN65/DN50

|

DN80/DN65

|

DN80/DN65

|

|

Work Pressure (max)

|

6

|

6

|

8

|

8.5

|

11

|

12

|

|

Outlet pressure (bar)

|

≧4

|

≧4

|

≧4

|

≧4

|

≧4

|

≧4

|

|

Number of impellers

|

4

|

4

|

4

|

4

|

3

|

3

|

|

Overall Weight (kg)

|

48

|

69

|

86

|

142

|

211

|

242

|

|

Material

|

HT250/316L

|

HT250/316L

|

HT250/316L

|

316L/ Super duplex steel

|

316L/ Super duplex steel

|

316L/ Super duplex steel

|

|

Price (RMB)

|

9960/17600

|

11000/18800

|

11960/19800

|

53600

|

59600

|

73600

|

|

Remarks: Pump speed: appx.2900rpm/min, three-phase AC motor, 380V, protection level IP55, insulation level F, head 20-70M

|